Keep it cool, clean and dry. A smooth abrasive flow with dry compressed air.

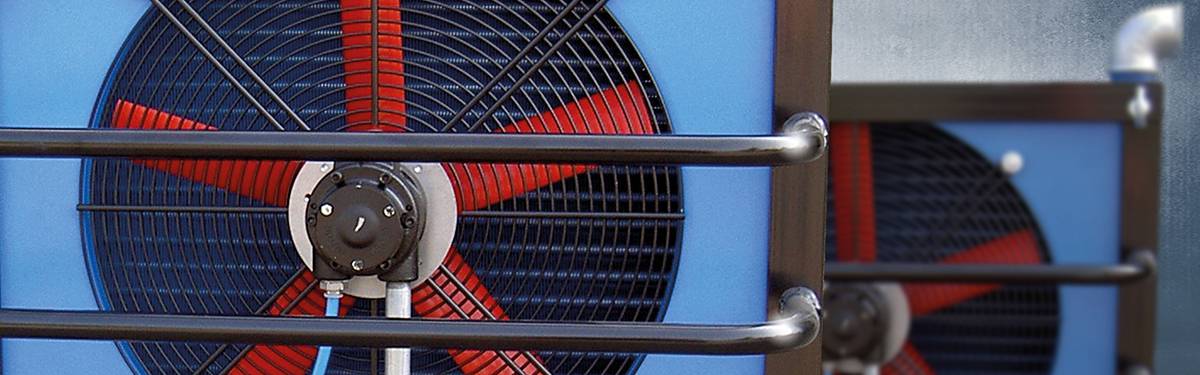

Aftercoolers from 10 to 30 m³/min

To enable trouble-free blasting the compressed air has to be as dry as possible. Gritco’s range of aftercoolers is designed to get the best possible compressed air, for small, mid-sized or large blasting systems.

To prevent blast pot blockages, secure a smooth, continuous abrasive flow with lesser breakdowns, wear and maintenance, compressed air needs to be cooled down (approximately at 9°C above ambient temperature). Because of this drop in temperature, water condenses and forms drops. These drops are removed by the aftercooler’s centrifugal separator. For even better clean air-results, optional compressed air filters can be fitted to remove oil and other containments.

The aftercooler is fitted with a pneumatic motor for easy everywhere use. For stationary use or compressed air savings an electric motor in 400V is available.

-

Powerful benefits

- Easy (re)moving and installation

- Quick setup in less than a minute

- Easy to use and accessible drainage system

- Optional automatic drainage

-

Better blasting value

- Trouble-free blasting production because of 80 - 85% moist extraction

- Nominal capacity model range of 10 to 30 m³/min (355 to 1060 CFM)

- Minimal pressure drops through large pipework

- Best performance at low energy costs because of optimal fan-design

- Wide choice of (optional) oil- and containment filters

-

Quality includes

- High quality heat exchanger with copper tubes and aluminum fins

- Grid protected cooling fins

- Durable powder coated finish

-

Better blasting economics

- Best possible blasting production because of trouble-free performance with less stops

- Saving on abrasive use by better metering possibilities with a smooth continuous abrasive flow

- Avoid costly, poor blasting results caused by wet compressed air