The right blast cabinet for every application

A good blast cabinet determines the quality and speed of your work. That is why Gritco not only supplies standard models, but above all solutions that fit your process. Whether it concerns tough rust, delicate surfaces or series production – with more than 35 years of experience, we ensure that you always make the right choice.

Which blasting cabinet is right for you?

Every blasting application is unique and requires a machine that optimally supports your process. With Gritco blasting cabinets, you increase efficiency, shorten turnaround times and achieve consistently high-quality results.

- Dry blasting – suction and direct pressure models for fast, powerful removal of rust and coatings or for optical finishing

- Wet blasting – delivers a much smoother surface than dry blasting and combines cleaning and degreasing in one step

- Soda blasting – high-quality cleaning and paint removal without changing the surface structure; completely residue-free

- Automatic blasting cabinets – maximum efficiency in series production and continuous operation

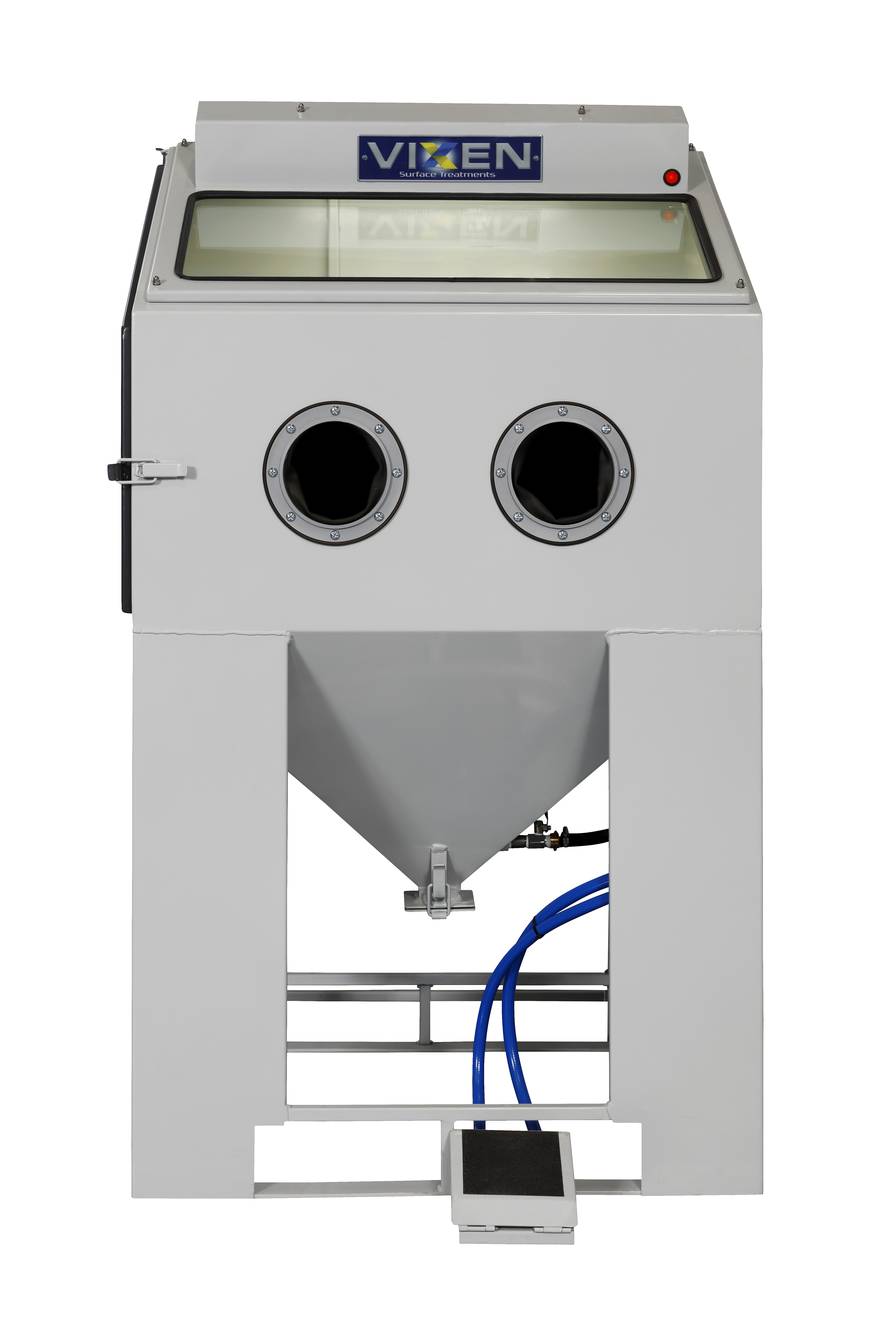

Our blasting cabinets

Frequently asked questions

-

What should you consider when buying a blast cabinet?

For dry and soda blast cabinets, effective dust extraction is essential. It must match the type of blasting, the blasting medium and the dimensions of the blasting room. This is the only way to ensure a clean working area and good visibility.

For wet blast cabinets, the choice of slurry pump is important. The centrifugal pump in our aquaBlast machines moves considerably more mass than, for example, a diaphragm pump, thus achieving a higher working speed.

-

What are the benefits of wet blasting?

In dry blasting, the abrasive bounces off the object after impact. With wet blasting, however, the abrasive is ‘packed’ in a mass of water, so it is still pressed over the object after impact. This results in a much smoother and compacted surface, which is especially advantageous for aluminium and stainless steel objects. The finish is outstanding and no longer prone to fingerprints. Moreover, it is a dust-free process and objects can be degreased and blasted at the same time.

-

What regular maintenance does a blast cabinet need?

A wet blast cabinet requires almost no maintenance because of the dust-free process and water lubrication between the abrasive and the machine parts.

In our dry and soda blast cabinets, the dust extraction filter cartridges are cleaned automatically. The collected dust must be disposed of regularly to ensure proper operation of the extraction. It is also important to add an equal quantity of new abrasive for optimal blasting results.

Request a free proposal

Every company is unique and every blasting application requires an individual approach. Therefore, we are happy to offer a free machine proposal tailored specifically to your needs.