Blasting parts

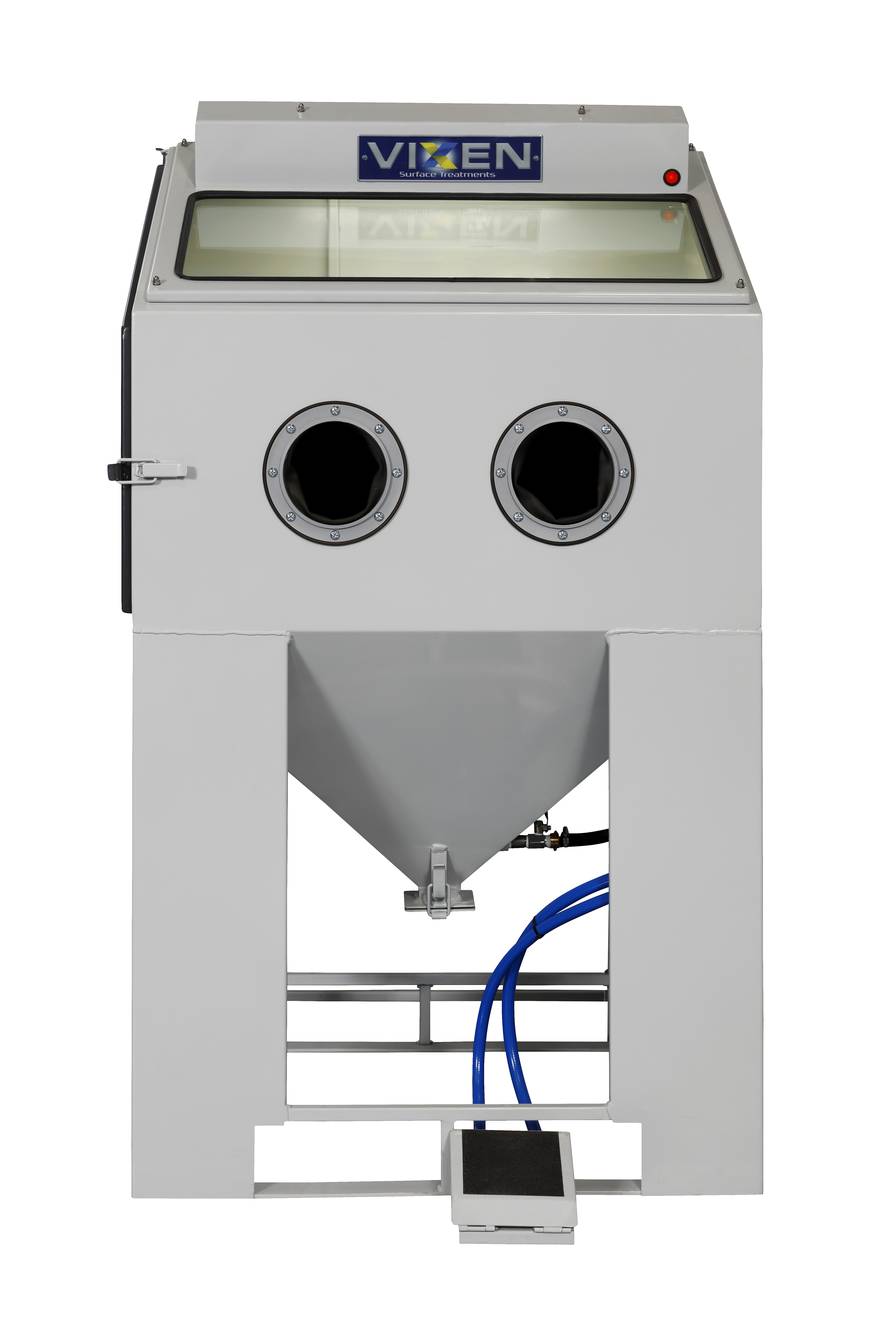

Gritco offers an extensive range of blast cabinets for both dry and wet blasting of parts. With 35 years of experience, designing and manufacturing soda blast cabinets is a Gritco speciality. Moreover, automatic blasting solutions are also part of our expertise.

The blast chain

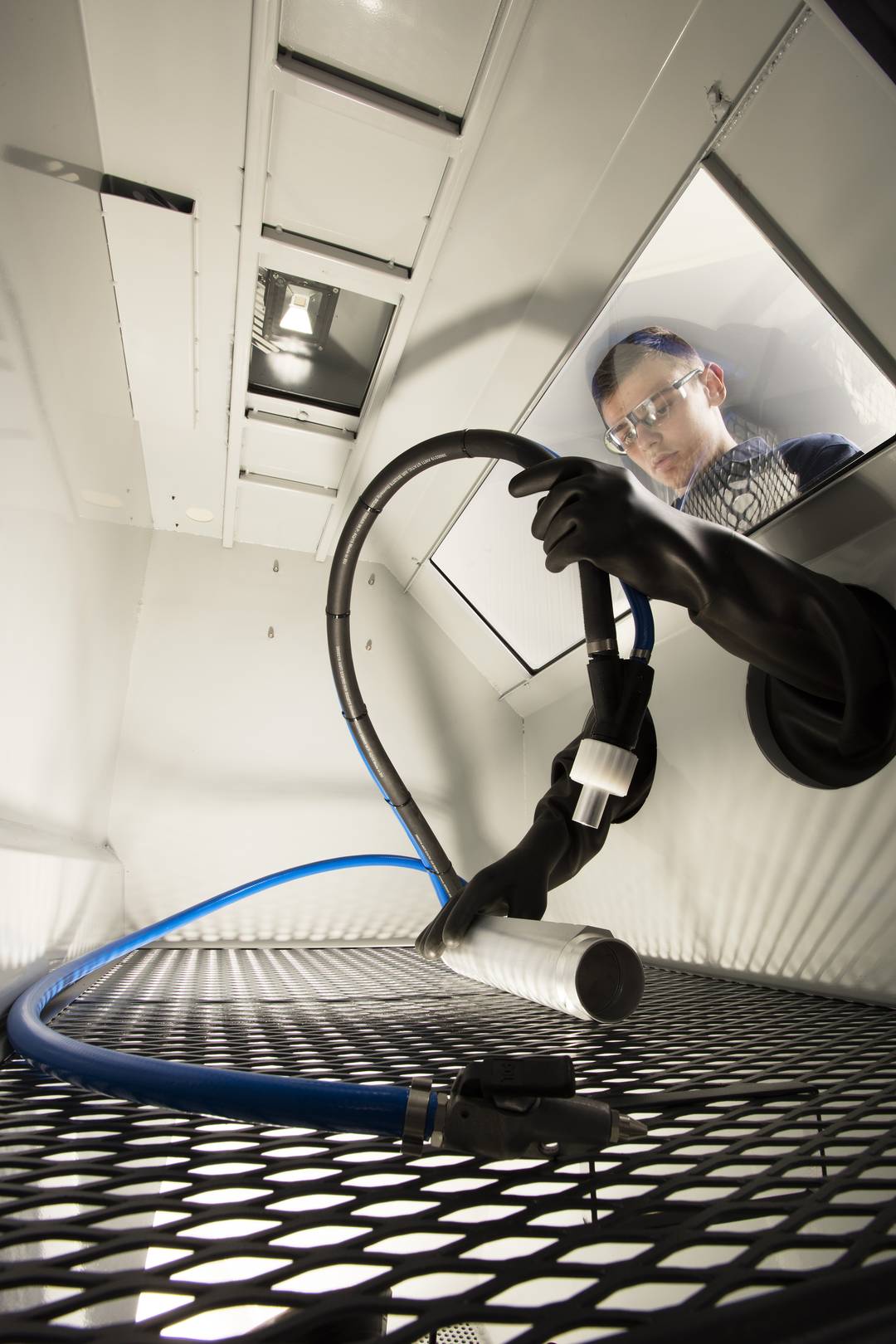

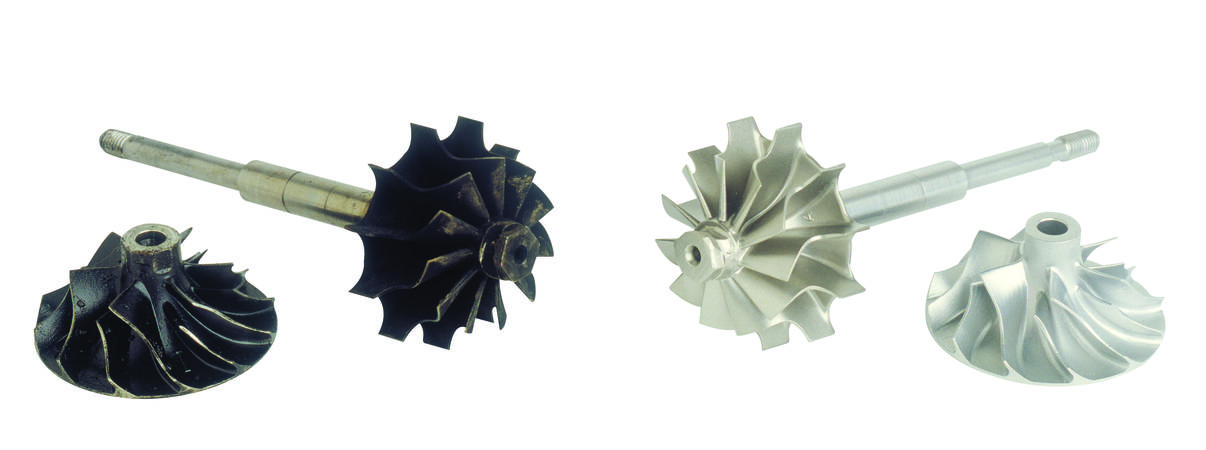

The type of object and the desired treatment determine which blasting method and blast cabinet are most suitable. An injector or pressure blast cabinet can be used to perform various operations ranging from paint and rust removal to surface embellishment. For exceptionally fine finishing of non-ferrous objects, a wet blast cabinet is an excellent choice, while soda blasting may be the best option for very critical parts.

Factors such as contamination type, material, desired finish and surface roughness all play a role in choosing the right abrasive. Abrasive reuse is very important, not only to save costs but also to maintain good visibility within the cabinet during the blasting process.

Most blast cabinets require a compressor with a capacity of 600 to 1,200 litres per minute (depending on the sort of blasting operation) to work quickly and efficiently. In addition, it is essential to ensure dry and clean compressed air to prevent clogging of the blasting media and optimise the quality of the blasted surface for subsequent production processes, such as paint spraying.

Our blasting cabinets

The right blast chain

Achieving the results you want requires the right composition of the blast chain to suit your situation. We can help with that.

In a (free) consultation, we determine together the alignment of the different links to achieve the best results at lower costs.