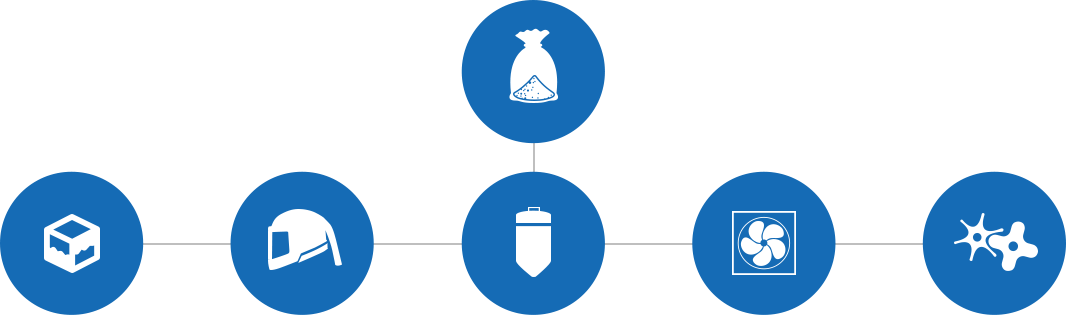

Dust suppressed blasting (vapour blasting)

Measuring up to required blasting quality results (removing paint and rust) without disrupting other processes is very well possible with Gritco’s reliable and easy-to-operate blasting equipment.

Gritco’s high quality blast pots

Next to extensive setting-possibilities of the abrasive amount that reduce dust production as well as purchase – and disposal costs, Gritco’s special Vapour blasting equipment allow the use of added water to the air- and abrasive stream. This feature reduces the dust production and abrasive rebound to a minimum and maximizes the additional Gritco advantages such as ease-of-use, reliability, low maintenance need and high performance.

Gritco’s aftercoolers

Trouble-free blasting with high quality surface results (ready for further processing) starts with dry air. Gritco’s aftercoolers (possibly extended with filters) are designed to prevent blast pot blockage with the best possible air for small, mid-sized or large blasting systems.

Gritco’s personal protection

As the amount of rebounding abrasives and dust is small, the use of a blasting helmet is advised but not mandatory. Adequate protection can be provided by a (approved) face shield.

The right choice of abrasives

The type of material and treatment of an object define the abrasive’s sort and size. As reclaiming and recycling wet abrasives is too complicated, one-pass-abrasives such as Olivine, Red Garnet, Glass Granulate or Aluminium Silicate (slag) are commonly used to remove rust and paint. The degree of contamination and required result (e.g. surface roughness) determine the abrasive grain size, which should be as small as possible to optimize blasting speed and cover rate.

The right compressor

“More power means more work” is especially true for the last part of the blasting chain: the compressor. More air means faster progress simply because of the possibility to use larger nozzles creating larger blasting patterns. Therefore compressor capacities can vary from 2 to 10 m3/min. More on compressor sizes here.

The blasting chain